Pump Servicing is an important part of the manufacturing process and can have a significant impact on product quality and production. By optimizing pump servicing procedures, you can boost productivity and quality while reducing downtime and costs. In this article, we will share with you tips for optimizing your pump servicing procedures to boost productivity.

What is Pump Servicing?

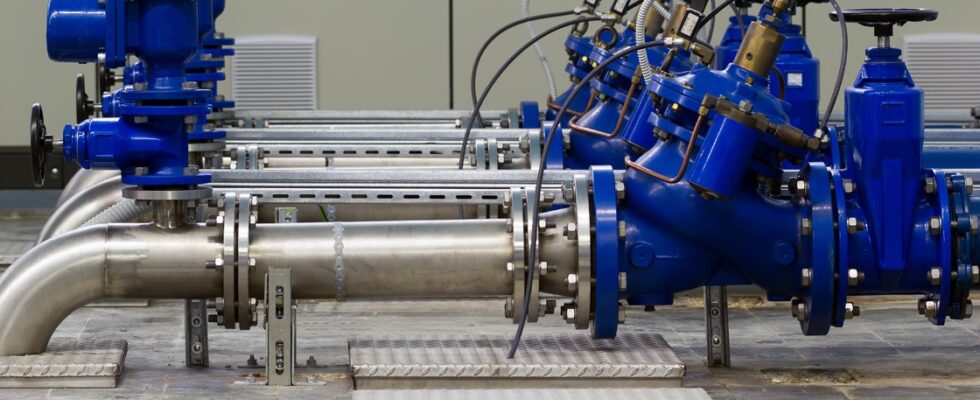

Pump servicing like the ones offered by Mega is the process of maintaining and repairing pumps. It can involve anything from regular cleaning and lubricating a pump to replacing worn parts. Servicing pumps is important to keep them running smoothly and efficiently.

Benefits of Pump Servicing

Most people are not aware of the many benefits that come from pump servicing. By having your pump serviced on a regular basis, you can avoid costly repairs and replacements, extend the life of your pump, and improve its efficiency.

How does Pump Servicing Work?

Pump servicing is the process of maintaining and repairing pumps. This can include everything from inspecting and cleaning the pump to replacing worn parts. Servicing pumps regularly can help to prevent problems and extend the life of the pump.

How to choose a Pump Servicing Company?

When choosing a pump servicing company, it is important to consider the company’s reputation, experience, and qualifications. Make sure to read online reviews and compare prices before making a decision. It is also important to choose a company that is properly licensed and insured.

5 Tips For Optimizing Your Pump Servicing Procedures To Boost Productivity

Here are the five tips for optimizing your pump servicing procedures:

1. Plan Ahead

Make sure you have a plan for when your pumps will need servicing and work to schedule these services around your manufacturing schedule.

2. Use the Right Tools

When it comes to pump servicing, it’s important to use the right tools and machines for the job at hand. This will help you to avoid downtime and improve productivity. Using the wrong tools can result in damage to the pump, which can lead to costly repairs or replacement.

3. Follow Guidelines

To ensure consistent quality and production, it is important to follow established pump servicing guidelines. These guidelines cover everything from proper maintenance and troubleshooting to safety procedures. By following these guidelines, you can help keep your pumps in top condition and prevent costly downtime.

4. Use Technology

Technology can be a great asset when it comes to servicing pumps. By using apps and other tools, you can improve your efficiency and keep track of your progress. This can help you get the job done faster and easier, and can also help you avoid potential problems down the road.

5. Hire a Pump Servicing Specialist

Working with small, specialized companies can help you to avoid any potential disruptions and improve quality and productivity.

In brief, we have shared with you tips for optimizing your pump servicing procedures to boost productivity. Check out Mega for their pump servicing specialist.