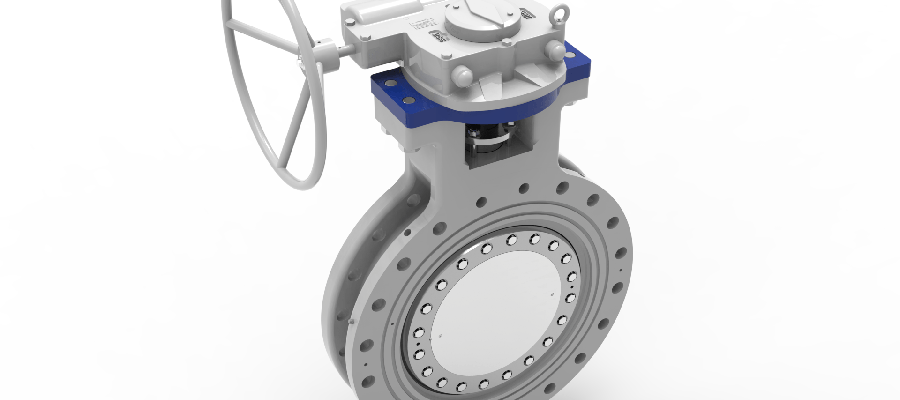

Butterfly valves are a type of rotational motion valve that’s used to shut off the flow of fluids in pipelines. They are frequently used as a way to control flow. They’re employed in various industries, including collection and distribution, water supply, and pumping stations, and they have a range of applications, particularly in flow isolation. Meanwhile, simple construction and compactness are two of the primary benefits they have over other valves, resulting in lighter weight and lower cost products with smaller assembly footprints and faster actuation rates. And the major parts of a butterfly valve are listed below:

Body

The valve’s body fits between the pipe flanges, with flanged, wafer ends and double lug connections being the most common.

Disc

The disc, linked to the valve body and acts as a gate to stop or throttle fluid flow, is comparable to a gate in a gate valve or a ball in a ball valve. The stem, or shaft, is usually drilled into the disc. Disc orientation, design, and material can all be altered to increase sealing, flow or operating torque. The 9881k double eccentric disc, for example, is intended to reduce seal wear and “scuffing”, along with operating torque needs.

Seals

Seals are used at several points within the valve to guarantee a tight seal during the performance or to segregate the process media from the valve’s structural components for a more adaptable and cost-effective design.

A continuous T-profile robust sealing ring seals the seat face and is maintained on the disc’s periphery by a holding ring, which prevents the sealing ring from tumbling out. The sealing ring is forced against the seat face in the closed state, establishing a snug fit on downstream and upstream ends. And because of the double eccentric disc design, the sealing ring is fully unstressed in the open position.

The multiple O-ring shaft sealing technology offers maintenance-free sealing for the valve’s lifetime by avoiding contact between both the process media and the stem/shaft. Furthermore, smaller, more common components like bearings, bushings, and fasteners are found in almost all valve designs.

Butterfly valves, depending on the requirement, can provide substantial benefits over other valves, particularly for sizes larger than DN 200 (200 mm), which are:

Compact and Lightweight

A butterfly valve has a reduced installation footprint due to its compact design and smaller face to face dimensions. It thus saves money in decreased installation costs such as equipment, labour, and piping support.

Low-Maintenance

Their maintenance requirements are greatly reduced thanks to an intrinsically simple, cost-effective design with few moving parts and fewer wear spots.

Rapid Action

A 90° rotation of the lever, or the actuation device, closes or opens the valve completely. On the other hand, larger butterfly valves frequently require a gearbox as an element of the actuation mechanism, which simplifies valve operation and decreases operational torque at the sacrifice of speed.

Low Price

Butterfly valves need less material, are easier to design and manufacture, and are often the more cost-effective option when compared to other valves. As such, larger valve diameters, often above DN 300, provide the most cost reductions.

Versatility

Butterfly valves can be used for various applications, including underground installation. In pipelines, butterfly valves are useful because they help control water flow. They can stop or start any fluid flow and change the flow of liquids. Meanwhile, some valves are excellent for high-pressure fluids, while others are better for corrosive systems.