Every entrepreneur is keen on improving the performance of their businesses to increase profits.

Many times, they will deliberate on the best ways to: enhance throughput, gain the flexibility they need to produce a vast range of products, prevent changeover from barring production, and understand how they can redistribute skilled employees to valuable tasks in their organizations.

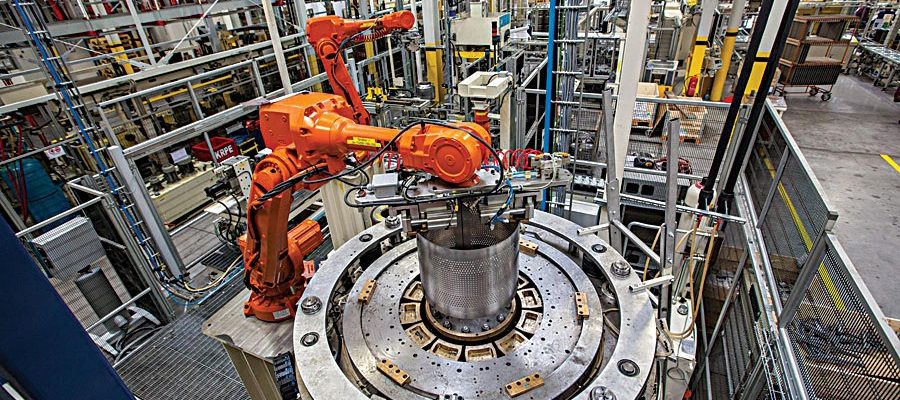

Many of the above-mentioned concerns can be solved easily with automation. Here is how businesses can enhance productivity in their assembly processes.

Robotic Assembly of Wooden Pallets

For companies to succeed in their operations, they need to take heed of the increasing demands from their customers. Workers may not be productive enough when working in a dangerous environment. For instance pallet building is not only dangerous but it’s also difficult.

With numerous wooden pallets available in the US alone and a big percentage of the same getting replaced annually to cope with the supply chain, there is a need for an efficient and dependable strategy of developing wooden pallets.

The demand for more durable, robust, and sustainable pallets increase, companies should deliberate on ways to accommodate the production of low volume/high mix production according to Universal Robots experts.

Many manufacturers today are realizing that the execution of robotic automation for wooden pallet assembly is beneficial in generating a flexible environment where custom and high-quality products can be produced.

Advantages of Robotic Assembly of Wooden Pallets

Even though dedicated pallet assembly machines are ideal for prolonged production, they can be expensive. Further, they may require a long period of time to execute a changeover. You can cut down the changeover time significantly by adopting industrial robots pallet assembly system.

This provides a more dependable production strategy for high mix manufacturing. Robotic manufacturing gives manufacturers the flexibility they require to develop custom block pallets and stringer in the same system and supports a wide variety of pallet sizes.

Robotic automation is perfect for short production runs of between 25 to 1,500 units. Robot assembly of pallets can generate up to 50 pallet blocks per hour or nearly 60 stringer pallets within an hour. To achieve a favorable return on investment, entrepreneurs should run the automation for two shifts at most.

Industrial robots from Universal Robots have been in existence for many years now and customers opine that they are robust, fast, precise, and provide users with dependable speed, repeatability, and payload capacity.

Companies should consider automating their assembly processes in order to eliminate employee fatigue, cut down injuries, and guarantee precise execution of tasks hence preventing reworks which can be costly. Companies that have already adopted robotic automation agree that they have boosted production and enhanced the quality of their products.

By deploying dangerous, dull, and dirty tasks involved in pallet building, a manufacturing plant can retrain decision makers and redistribute them to more valuable and exciting tasks in the company. This goes a long way in accelerating company growth and maintaining employees in other capacities within the company.

Robotic automation can double and sometimes even triple production capacity per person. Sticking to a regular maintenance schedule prolongs the lifespan of your robot and increase return on investment. Universal Robots incorporates the most qualified employees in the industrial robot manufacture process. This is why UR robots have been hailed for durability.

Robotic Assembly of Wooden Pallets Return on Investment

Robot systems are beneficial for businesses that generate a variety of pallets either over multiple shifts or in high volume. Robotic automation can facilitate assembly of one pallet each minute which translates to 480 per shift.

However, fixed machinery is still the most dependable when it comes to producing high volumes of similar pallet size and type. The biggest return on investment benefits emanates from the robotic system’s capability of producing various pallet types with reduced downtime during a changeover.

Finally

When budgeting for robotic system companies should consider the expected return on investment that the new system is bound to offer as well as the anticipated payback period.