Top Industries offer an inline pallet inverter system. It is a blend of pallet turner and pallet transfer system. The process is completely automatic, which helps businesses reduce manual labor dependence and increase productivity. The inline inverter system is compatible with other applications like slip sheet dispensers, labeling machines, roller conveyors, pallet stackers, and more.

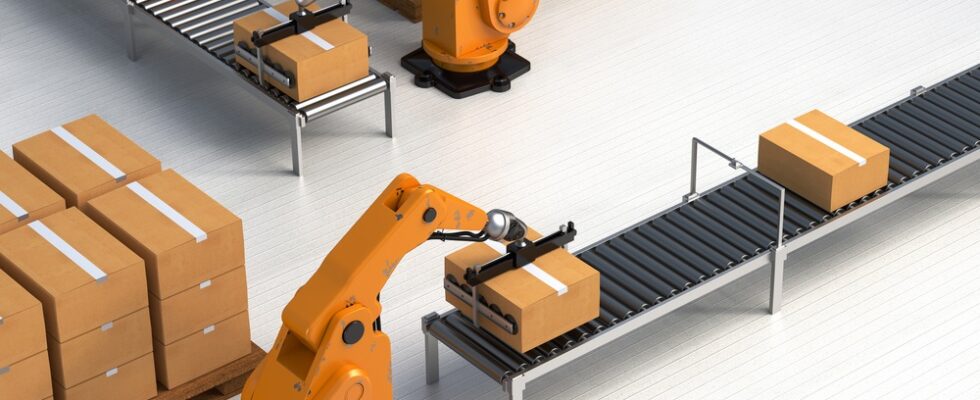

Inventory palletizing is essential to carry boxes in bulk. It is incorporated in different modes depending on the product nature that needs to be dispatched or shipped. You are wondering why stack goods in a single unit or what are the benefits of an inventory palletization system.

Better consistency

Consistency is essential for successful palletization. Uneven layers, crooked products, and gaps can ruin the pallet’s structural integrity. It can cause products to topple down during transit.

Human errors are inevitable, but automatic palletizers are designed for precision and accuracy every time. Pallets are correctly stacked, which lessens the possibility of product damage, thus the unit load is delivered safely to its destination.

Decreases labor cost

The manual palletization process is labor-intensive, time-consuming, and tedious. An automatic palletizer increases the task speed, thus the staff is released to do more crucial tasks. Thus better use of labor costs can be made.

Quick handling

In the palletization process, the basic feature is to place products on the pallets. One palletized goods unit is called a unit load, which involves several boxes stacked in layers. The machines carry several unit loads at once, which ensures quick handling. It is essential for temperature-sensitive perishable goods handling and shipment.

Optimized functioning

Today, palletization is getting more and more efficient. It is because of innovative palletization systems. There is a semi-automated and automated palletizing solution that has enhanced the efficiency of warehouse and logistic functions.

Decreased risk

Inventory palletization ensures goods safety, especially bulky items. Goods stored in warehouse facilities can be bulky and valuable, so carries a high risk of loss or damage. Pallets are designed to bear massive load capacity and have a flat, strong bottom. If bulky, valuable products are palletized businesses can stay assured that their items are safe.

Reduces occupational hazards

Manually stacking pallets needs repetitive movements like lifting, bending, and stretching. This can induce consistent muscle strain, which is associated with a workplace injury. It can cost businesses money, time, and most valuable workers. An automatic palletizing system puts safety first and creates a productive environment.

Easy transportation

Palletization enables to carry-off of multiple goods in many unit loads at once. This makes goods transportation easy hassle-free, and quick.

Enhances worker retention

Preserving a valuable labor force is essential for a low turnover rate. Manual stacking and moving pallets is a laborious process, which results in the loss of workers. With an automated palletizing process, the operators agree to take responsibility for the secondary packaging process. The team finds the working environment more compatible because they perform tasks as well as maintain equipment with ease.

Retain happy consumers

Inventory palletization ensures that your consumers receive safe products. Dented cans or crushed boxes are not sellable, so your consumers feel unsatisfied. An automatic palletizing system offers reliability and consistency in delivering products without damage.

Top Industries have a YouTube profile, where you can see how their inline pallet turner system works.